Auwell

To meet our customer’s expectation of lower manufacturing cost and better product quality ,AUWELL has been implementing our company’s industrial 4.0 plan step by step.

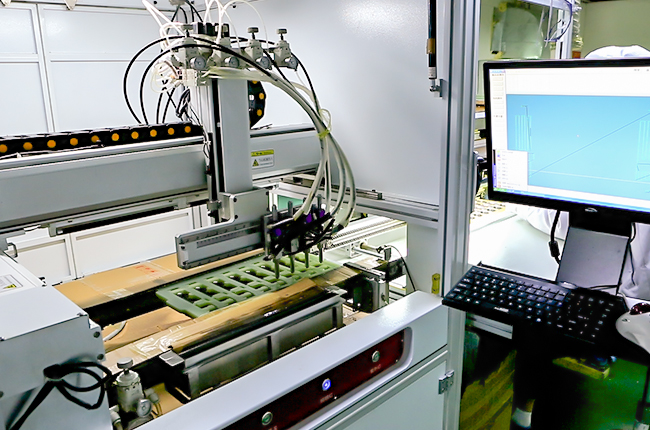

In the 1st stage of Smart manufacturing ,we optimize existing manufacturing process in addition to eliminating manual process and material handling. we imported the first-class brand of automation equipments and combined with our years of manufacturing experience independently developed automation testing equipment ,such as SIEMENS automatic solder paste printer SIEMENS high speed mounted and function mounted machine, ERSA 10-zone thermal reflow oven, automatic plug-in machine ,automatic conformal coating machine ,automatic ICT and FCT tester, etc. Bandary is going to link production machines and upgrade and integrate with Manufacturing Execution System (MES),and implement big data analysis tools to achieve higher productivity and excellent quality .In the 2nd stage ,we will integrate product design chain and order fulfillment through customer.

We now have 5-automaitc SMT production lines ,5-automatic DIP production lines,2-automatic ICT&FCT testing line ,1-automatic conformal coating line ,2-finished product assembly lines and a large number of advanced inspection and testing instruments ,with an annual production capacity of 5million control boards and 1million complete machines .At present ,our company’s automation level has reached 50% and we plane to increase it to 90% within 3-year.Our goal is no matter small order or big order can be produced in our automatic line,AUWELL continuously supports our customers to be successful in winning the market through our smart automation strategy .It is a great WIN-WIN strategy for both our customers and AUWELL.

Automation Strategy

Shorter product life cycle and more customized products are becoming the primary trend in today's market. Auwell is ready to take the challenge via developing highly flexible and modular common platforms with fast change over capability for high mix low volume products by adopting proven technologies and constantly developing new ones in automation while investing in R&D resource for future roadmap, Auwell is implementing more automation in different manufacturing processes to help our customers to gain competitiveness.

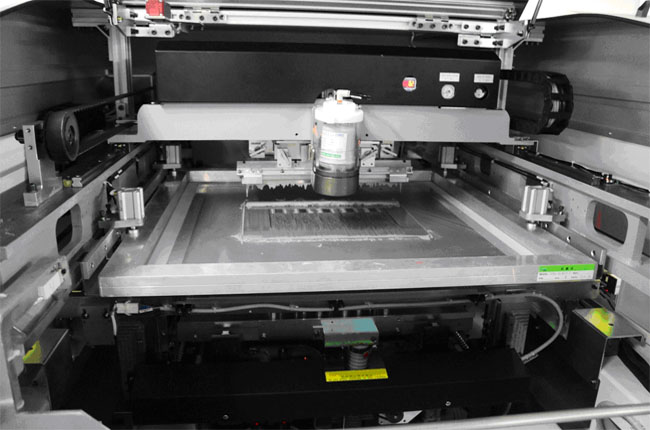

Auto solder paste

• Accuracy :+/- 12.0um@6 (Cpk2)

• High-precision printing of ultra-fine solder pad0201008004 inch components to large circuit boards.

• 2D solder paste detection function is used to confirm the printing effect.

• Automatic supply function of canned solder paste can maintain welding quality and mass production.

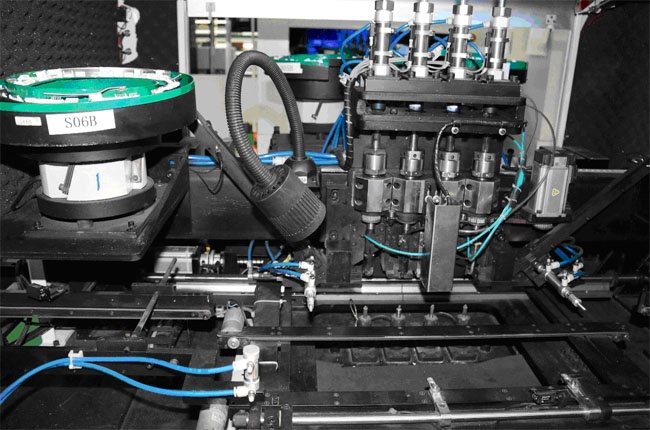

Auto DIP

• High speed load /unload function

• Auto collect production& quality data through industry 4.0 applications

• Higher productivity with automatic continuous supplement

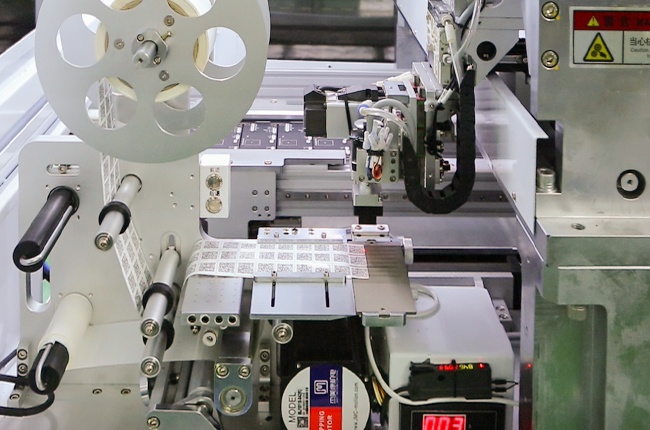

Auto labeling

• Modular &flexible design to cover all products and perform fast change over time

• Implement high accuracy CCD to recognize PCBA position and have label sticking accuracy+/-0.1mm

• Eliminate quality risk of PCBA component broken induced by manual sticking

• Triple throughput compared to manual sticking

• Process flow control and trceability through Industry 4.0 applicantions

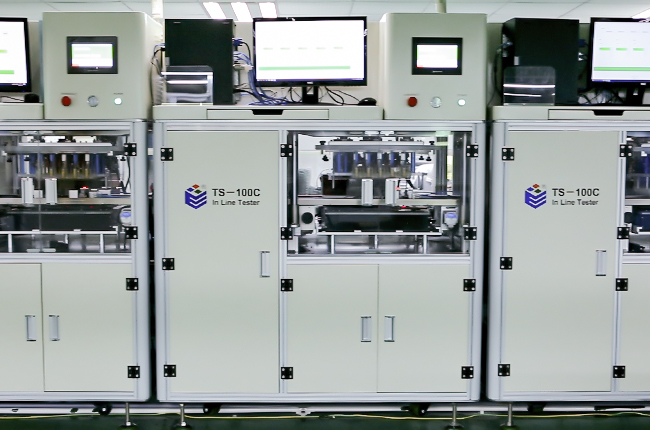

Auto ICT &FCT ( Auto in circuit &function circuit test)

• Automatic production and testing line was developed by Bandary at the basic of ICT and semi-automatic FCT .

• This automatic production line contains process automation ,transferring automation ,and product inspection automation .

• Not only improve labor productivity and product quality ,and also save labor cost ,and provide more competitive price to customer .

Underfill Adhesive Dispensing

• Higher adhesive dispensing quality and reliability on high density Sip module

• Better productivity and eliminate manual handling risk

• Lean concept to minimize WIP

Capabilities

Product

Contact Us

Contact name: Owenly lee

Phone: +86-0755-23049300

E-mail: owenlylee@bandarytech.com

Address: 2nd Floor A-Building A Bao Industry Park, No.160 Luyuan Road, Keyuancheng, Tangxia Town Dongguan City, China